Several conditions must be met for OSHA to issue a General Duty Clause violation:

Several conditions must be met for OSHA to issue a General Duty Clause violation:

- The hazard was recognized.

- The employer failed to keep the workplace free of a hazard to which his or her employees were exposed.

- A feasible and useful method was available to correct the hazard.

- The hazard was causing or likely to cause death or serious injury.

Recognition of a hazard can be established if the employer knew about the hazard. This can be ascertained through the employer’s previous inspection history. For instance, a compliance officer suggesting a particular situation may constitute a hazard could, given the right conditions, cite the employer on a second inspection for the hazard under the General Duty Clause.

OSHA also can use employee complaints or the employer’s own statements to determine if the hazard was recognized. In addition, the hazard can be recognized by the employer’s industry.

“OSHA does not necessarily need to show that a cited employer recognized the hazard,” Tucker said. “For purposes of the General Duty Clause, a recognized hazard exists if the hazard is recognized either by the employer or by the employer’s industry.” The existence of consensus standards or industry practices also can provide evidence that the hazard was recognizable, Tucker added.

Employees must be exposed to the hazard, and they must be the employees of the cited employer. An employer who creates, contributes to or controls a hazard that would otherwise be a General Duty Clause violation cannot be cited as such if his or her own employees are not exposed to the hazard, according to OSHA’s Field Operations Manual, an agency reference document that identifies inspection duty responsibilities.

Situations such as a multi-employer worksite can be more complicated. OSHA would have to establish that the workers exposed to the hazard were employed by the employer.

A feasible means of abating the hazard also is necessary, and that requirement places a burden on OSHA, Hammock said. In the rulemaking of a typical standard, OSHA has to demonstrate a feasible means of abatement. When a violation of a standard is issued and the employer contests, the burden falls to the employer to provide evidence as to why the abatement methods outlined in the standard are not feasible.

However, with the General Duty Clause, that burden shifts to OSHA, according to Hammock. Similar to establishing hazard recognition, OSHA said it can rely on consensus standards to show how a hazard cited under the General Duty Clause may be abated.

When OSHA issues a General Duty Clause violation, it is for the hazard, not for a particular incident or lack of a particular abatement method.

The hazard must be serious, meaning it could cause death or substantial physical harm. Establishing whether a hazard is serious is similar to how OSHA classifies a serious violation for its standards, the Field Operations Manual states. A serious hazard presents a “substantial probability” of death or serious physical harm.

As an example, the Field Operations Manual offers an employee standing at the edge of an unguarded floor 25 feet high. A fall likely would result in death or serious injury.

via The General Duty Clause.

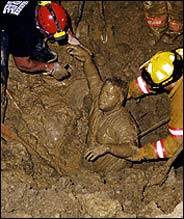

Cave-ins are perhaps the most feared trenching hazard. But other potentially fatal hazards exist, including asphyxiation due to lack of oxygen in a confined space, inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities.

Cave-ins are perhaps the most feared trenching hazard. But other potentially fatal hazards exist, including asphyxiation due to lack of oxygen in a confined space, inhalation of toxic fumes, drowning, etc. Electrocution or explosions can occur when workers contact underground utilities.