Three Department of Labor (DOL) agencies have responsibility for the administration and enforcement of the laws enacted to protect the safety and health of workers in America.

Three Department of Labor (DOL) agencies have responsibility for the administration and enforcement of the laws enacted to protect the safety and health of workers in America.

OSHA administers the Occupational Safety and Health (OSH) Act.

Safety and health conditions in most private industries are regulated by OSHA or OSHA-approved state systems.

Nearly every employee in the nation comes under OSHA’s jurisdiction with some exceptions such as miners, some transportation workers, many public employees, and the self-employed.

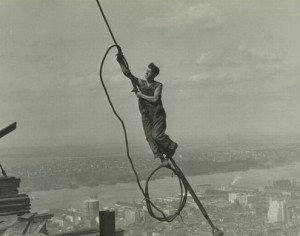

Employers subject to the OSH Act also have a general duty to provide work and a workplace free from recognized, serious hazards.

Mine Safety and Health Administration

DOL’s MSHA has responsibility for administration and enforcement of the Mine Safety and Health Act of 1977, which protects the safety and health of workers employed in the nation’s mines.

The Act applies to all mining and mineral processing operations in the United States, regardless of size, number of employees, or method of extraction.

The Fair Labor Standards Act

FLSA contains rules concerning the employment of young workers, those under the age of 18, and is administered and enforced by DOL’s Wage and Hour Division. Intended to protect the health and well-being of youth in America, the FLSA contains minimum age restrictions for employment, restrictions on the times of day youth may work, and the jobs they may perform.

Other resources

Office of Workers’ Compensation Programs – Administers four major disability compensation programs which provide wage replacement benefits, medical treatment, vocational rehabilitation and other benefits to certain workers or their dependents who experience work-related injury or occupational disease.

Office of the Ombudsman for the Energy Employees Occupational Illness Compensation Program (EEOMBD) and the SHARE initiative also play a role in the administration of DOL workplace safety and health programs.

For help in determining which safety and health standards apply to particular employment situations, select from the subtopics lists. Also, see the Office of Compliance Assistance Policy’s Web pages on safety and health in the workplace.

via U.S. Department of Labor — Find It By Topic — Workplace Safety & Health.