via 7 Keys for Creating a Safety Culture « Aubrey Daniels’ Blog Aubrey Daniels’ Blog.

via 7 Keys for Creating a Safety Culture « Aubrey Daniels’ Blog Aubrey Daniels’ Blog.

Following are seven keys to an effective safety culture:

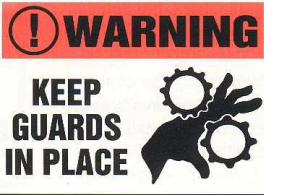

1. The entire workforce relentlessly pursues the identification and remediation of hazards. Correcting hazards as quickly as possible and maintaining good communications around hazards will not only create a safer workplace, it will improve your employees’ engagement. Frontline employees who believe management takes care of hazards are more willing to participate fully in safety initiatives.

2. Employees at all levels are equally comfortable stopping each other when at-risk behavior is observed and recognizing each other when safe behavior is observed. While good constructive feedback is important for improvement, positive reinforcement for safe behavior is essential for building safe habits. The more actively involved all levels of the organization are in delivering positive reinforcement for behaviors consistent with the desired culture, the stronger the culture will be.

3. No one is blamed for near misses or incidents. Instead, systemic causes are pursued. Often when people engage in at-risk behaviors that lead to incidents, there are organizational systems and practices that inadvertently encourage those at-risk practices. It is important to uncover those and establish accountability for making the changes to the systems and practices to encourage safe behavior.

4. The fear of discipline which drives under-reporting and stifles involvement has been driven out of the culture. Discipline has a place, but most safety issues can be effectively dealt with without discipline, which has side effects that work against building a culture of safety. When discipline is used disproportionately in relation to positive consequences it leads to lower morale, reduced trust, lower productivity, less teamwork and lack of engagement. Equally disturbing is that it suppresses reporting incidents which cripples the organizations ability to learn from mistakes and become more proactive.

5. The workforce is characterized by good relationships at all levels. Trust is an essential component for an effective safety culture. As noted above, mistakes and errors, while unfortunate, provide invaluable learning. Employees who have good working relationships with management are more likely to speak openly and honestly about what is working, what is not and what still needs to change. They are also more engaged in other aspects of safety.

6. Safety is integrated into day-to-day work. It is not treated as something separate to be discussed during a weekly safety meeting or only at shift change. Safety should be part of every conversation and considered in every decision.

7. Successes are celebrated along the way. Pride shouldn’t be focused solely on a company’s safety record, but also in what is being done every day, all day to achieve that record.

Once you have defined the ideal safety culture for your organization, the science of behavior analysis can be used to develop behaviors consistent with that culture. Targeted positive reinforcement of desired behaviors leads to rapid change and the effects multiply quickly as all employees begin to not only display desired cultural behaviors, but to reinforce those behaviors in others.

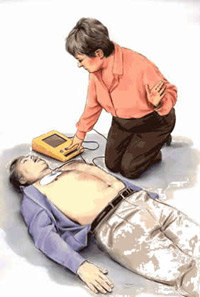

Rates of musculoskeletal injuries from overexertion in healthcare occupations are among the highest of all U.S. industries. Data from the Bureau of Labor Statistics (BLS) show that in 2011, the rate of overexertion injuries averaged across all industries was 38 per 10,000 full time workers.By comparison, the overexertion injury rate for hospital workers was twice the average (76 per 10,000), the rate for nursing home workers was over three times the average (132 per 10,000), and the rate for ambulance workers was over six times the average (238 per 10,000). The single greatest risk factor for overexertion injuries in healthcare workers is the manual lifting, moving and repositioning of patients, residents or clients, i.e., manual patient handling.

Rates of musculoskeletal injuries from overexertion in healthcare occupations are among the highest of all U.S. industries. Data from the Bureau of Labor Statistics (BLS) show that in 2011, the rate of overexertion injuries averaged across all industries was 38 per 10,000 full time workers.By comparison, the overexertion injury rate for hospital workers was twice the average (76 per 10,000), the rate for nursing home workers was over three times the average (132 per 10,000), and the rate for ambulance workers was over six times the average (238 per 10,000). The single greatest risk factor for overexertion injuries in healthcare workers is the manual lifting, moving and repositioning of patients, residents or clients, i.e., manual patient handling.